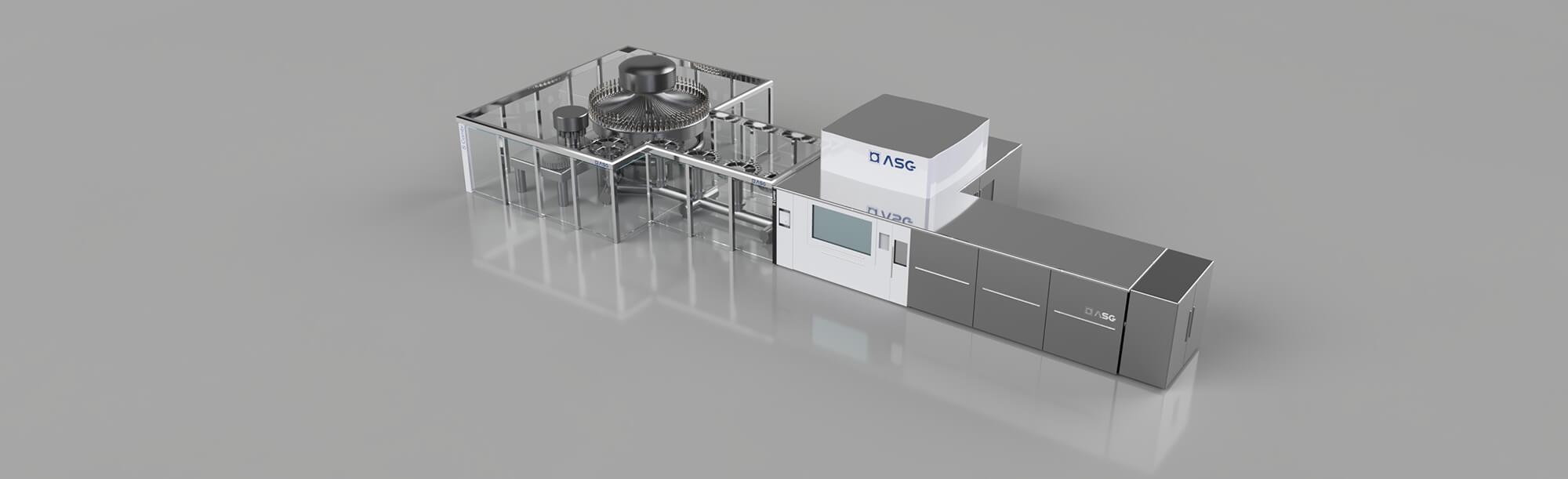

Ultra-clean combiblock

ASG Ultra-Clean Combiblock integrates functions of blowing, disinfection, cleaning, filling and capping to ensure the health and safety of beverages. There are specific type of ultra-clean combiblock, ultra-clean hot filling with filling temperature between 82-92 °C, ultra-clean medium temperature filling with filling temperature 68-75 °C.

Main Features:

Main Features:

- Friendly HMI with multi-languages.

- Advanced reflection system by ceramic plate, heat-preservation system and heating system, preform can be heated evenly.

- Special design high-pressure gas recovery system can saves more than 30% of compressed air.

- Ionized de-duster can be equipped to improve the cleanliness of the packaging container.

- The tailored made servo stretching system can be adapted to preforms with various stretching ratio, achieving the variable speeds and high accuracy positioning.

- The filling valve is designed with the tidy and safe valve body, the material quality can be fully guaranteed.

- A sterilization process for a variety of packaging materials to meet the needs of various products.

- Filling methods with a variety of flow rates can achieve alternate filling speeds to meet different characteristics of beverage filling.

- Disinfectant-immersed or in-line spray-type bottle cap sterilizer.

- Automated process inspection, control, and data report and record systems to provide aseptic monitoring for all key aspects of the production line.

- Complete CIP, COP, SIP, SOP cleaning systems to ensure the process safety of the filling environment.