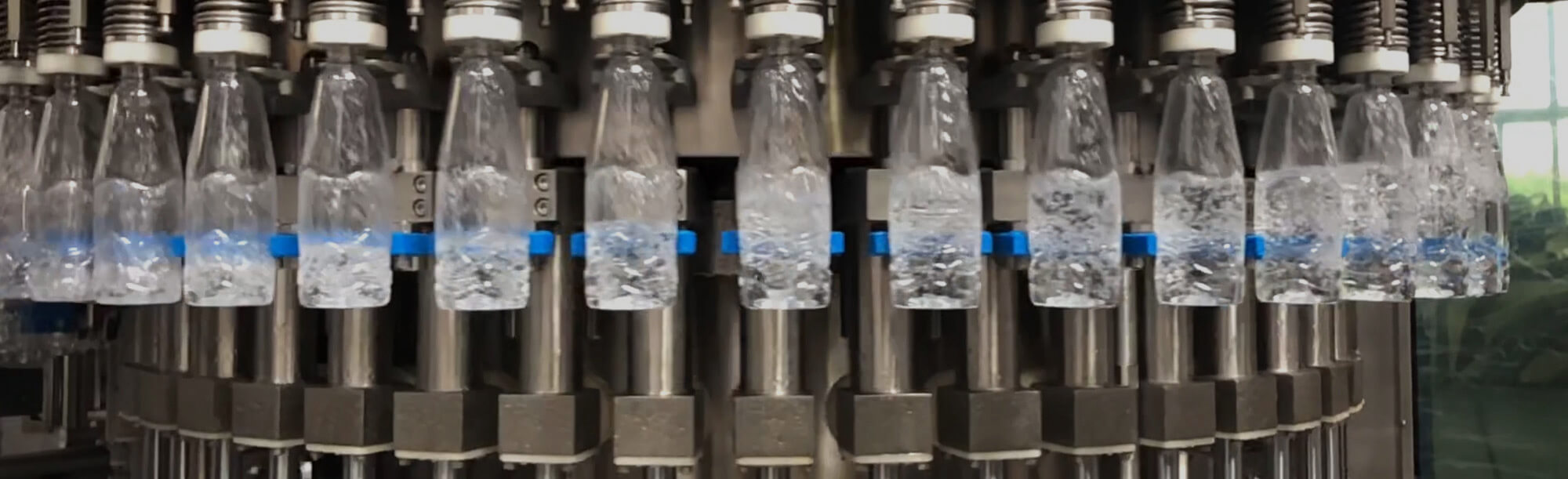

Ultra-clean filling

The ASG ultra-clean filling machine has high capacity, great reliability and efficiency, suitable for energy drinks, juices, and tea, etc.

Perfect for energy drink and juice-based beverages

ASG ultra clean filling machine is also a fully automatic moderate temperature liquid food packaging equipment. Which integrates empty bottle conveyor system, empty bottle sterilization system, empty bottle washing system, automatic filling system, and automatic sealing system. The device is the first medium temperature liquid food packaging equipment that is suitable for low acid beverages (such as juice, dairy products, tea drinks, functional drinks, etc.). In the case of aseptic cold filling and the same bottle sterilization process, the filling temperature is lower than that of high temperature and higher than normal temperature. The filling temperature is generally 65-70 degrees. Under the condition of guaranteeing the shelf life of the bottled beverage, the weight of the packaging container is reduced, so that the weight of the packaging container is reduced from 28 grams per 500ml to about 23 grams per square meter, and the effect of energy saving and consumption reduction is obvious.

Ultra-clean filling machine

Perfect for energy drink and juice-based beverages

ASG ultra clean filling machine is also a fully automatic moderate temperature liquid food packaging equipment. Which integrates empty bottle conveyor system, empty bottle sterilization system, empty bottle washing system, automatic filling system, and automatic sealing system. The device is the first medium temperature liquid food packaging equipment that is suitable for low acid beverages (such as juice, dairy products, tea drinks, functional drinks, etc.). In the case of aseptic cold filling and the same bottle sterilization process, the filling temperature is lower than that of high temperature and higher than normal temperature. The filling temperature is generally 65-70 degrees. Under the condition of guaranteeing the shelf life of the bottled beverage, the weight of the packaging container is reduced, so that the weight of the packaging container is reduced from 28 grams per 500ml to about 23 grams per square meter, and the effect of energy saving and consumption reduction is obvious.

Ultra-clean filling machine

- Maximum output capacity 36,000 BPH(standard size).

- Adopt technology of air conveyor direct connect with bottle infeed starwheel. The bottle infeed starwheel adopts innovative neck holding mechanism with bottle separating function which saves bottle infeed screw and conveyor.

- Bottle transferring is by bottleneck holding way. Easy to changeover parts, It takes only 10 minutes to changeover bottle size.

- Specially designed stainless steel gripper for rinser which is solid and durable, no contacting bottleneck to avoid second contamination to bottleneck.

- High-speed and mass flowrate filling valve is easy to clean, with perfect CIP loop and control program.

- The bottle-out starwheel is a helical structure.