ASG Blowing-filling-capping Combi Block

ASG Blowing-filling-capping combi block is based on rich and successful experience of complete line projects from ASG.

Which is an integrated solution merging several technology including stretch blow molding, filling process, capping equipment and intelligent integration innovation. The Combi system is composed of the following six main systems: preform loading system, preform unscrambler, preform heating system, stretch blow molding, filling, capping and electrical integration system.

Save more

Take 3600 bottles/hour (500ml) waterline as an example, compared to traditional split technology.

60%

Save up to 60% space than regular production line

30%

Save up to 30% water usage

15%

Save up to 15% electric power usage

20%

Require up to 20% less total investment

A

Automatic preform detection and elimination

B

Simple setup adjustment to fit different sizes of preform

C

Optimized design for daily maintenance and cleaning

Processing range

Mineral water, still water, non-carbonated

PET bottle with round or square

Volume up to 2.0 L

Flat or sport closure

Preform loading

- Automatic preform detection and elimination

- Simple setup adjustment to fit different sizes of preform

- Optimized design for daily maintenance and cleaning

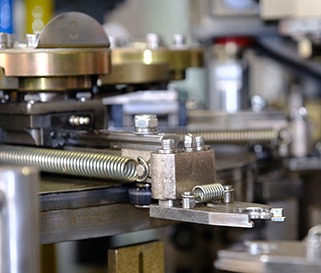

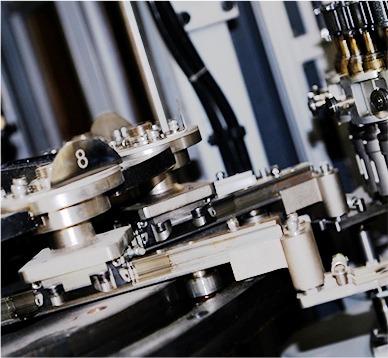

Stretch blow molding

- Up to 2,200 containers per hour per cavity

- mproved stretch blow molding unit

- Require less compressed air

- Automatic preform detection and elimination

- Optimized design for daily maintenance and cleaning

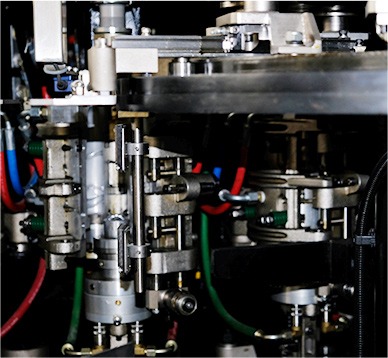

Filling

- Mass flow meter for filling as an optional

- Infinitely variable filling speed

- Product filling from the top

- Special design ensure safety and hygiene

- Optimized design for daily maintenance and cleaning