How to Realize Bottle Blowing Technology?

Bottle blowing technology is grabbing the attention of many machine manufacturers across the globe. Bottle blowing is a manufacturing method through which the hollow parts of plastic are created. It is easy to join these parts with the help of this technological innovation. Moreover, this technology is used to create glass bottles and shapes.

How to Realize Bottle Blowing Technology?

Bottle blowing technology is divided into diverse categories. Each category has its advantages. This blowing method starts with the melting of the plastic and shaping it into the parison. This parison is compressed to form a mold. The blowing machine is used to pass air through this mold due to which the plastic comes out from the mold. Now, the plastic is cooled down to form the desired shape. At the moment, we are going to tell you about the bottle blowing technologies.

Extrusion blow molding

With the help of extrusion blowing technology, the plastic is first melted down and then extruded into the parison. After that, it is caught by closing it into the metal mold that has a low temperature. Air is passed through the parison due to which it inflates into the form of the hollow container. When the plastic comes out, then it is important to lower down its temperature. When it cools down, then the mold is opened, and the part is taken out of it. Basically, there are two types of extrusion blowing technology, which includes intermittent and continuous technologies. The automatic PET blowing machine performs the extrusion blow molding process efficiently.

Injection blow molding

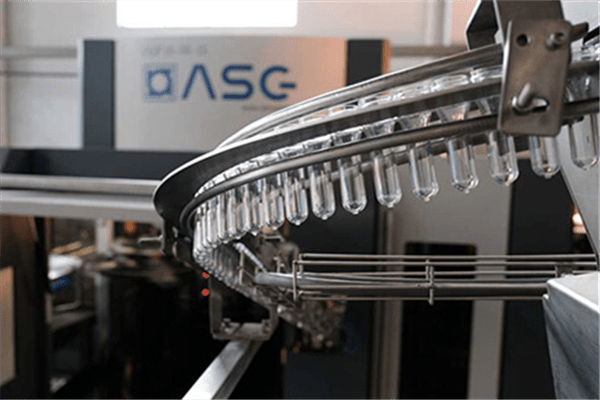

To perform the injection blow molding, the companies make use of the injection blow molding machine. This machine has the capacity to form plastic and glass bottles. It does not matter whether you want to produce these items in large numbers or small; the injection blowing technology will be useful for you.

In this method, the polymer is injected onto the main pin. The machine rotates this pin to the blow molding station. Afterward, it is cooled down, and the part is taken out. The injection blow molding machine performs three main steps automatically, which includes injection, blowing, and ejection

Stretch blow molding

The stretch blow molding process is divided into two categories. These categories are known as two-stage and single-stage methods. The latter one is broken down into 4-station machines. However, in the two-stage stretch blowing method, the plastic is molded into its preform by making use of the stretch molding method. The preforms are designed with the help of the bottle necks. When these preforms are designed, then they are packaged and cooled down after reheating.

Final Words

From the above explanation, it would be easy for you to understand how the bottle blowing technology has been realized. Diverse types of machines are involved in performing diverse technologies. Like the PET blowing machine is used to produce PET glass bottles. It follows the working principle of the extrusion blow molding. However, some of these machines follow other molding techniques.