Rotary stretch blow molding

Sustainable, efficient and high capacity production of PET bottles

ASG automatic rotary stretch blow molding machine is absorbing the most advanced of the current global production technology, successfully self-developed high-speed rotary blow molding machine. It consists of rotating main blower, heating furnace, an automatic feeding device, electrical control system and pneumatic control system. The machine gets the advantages of high automation, stable and reliable machine performance, high production efficiency and low production cost.

Stretch blow molding machine:

ASG automatic rotary stretch blow molding machine is absorbing the most advanced of the current global production technology, successfully self-developed high-speed rotary blow molding machine. It consists of rotating main blower, heating furnace, an automatic feeding device, electrical control system and pneumatic control system. The machine gets the advantages of high automation, stable and reliable machine performance, high production efficiency and low production cost.

Stretch blow molding machine:

- The touchscreen HMI enables all-around control of the production process in each independent zone and time monitoring for bottle blowing process.

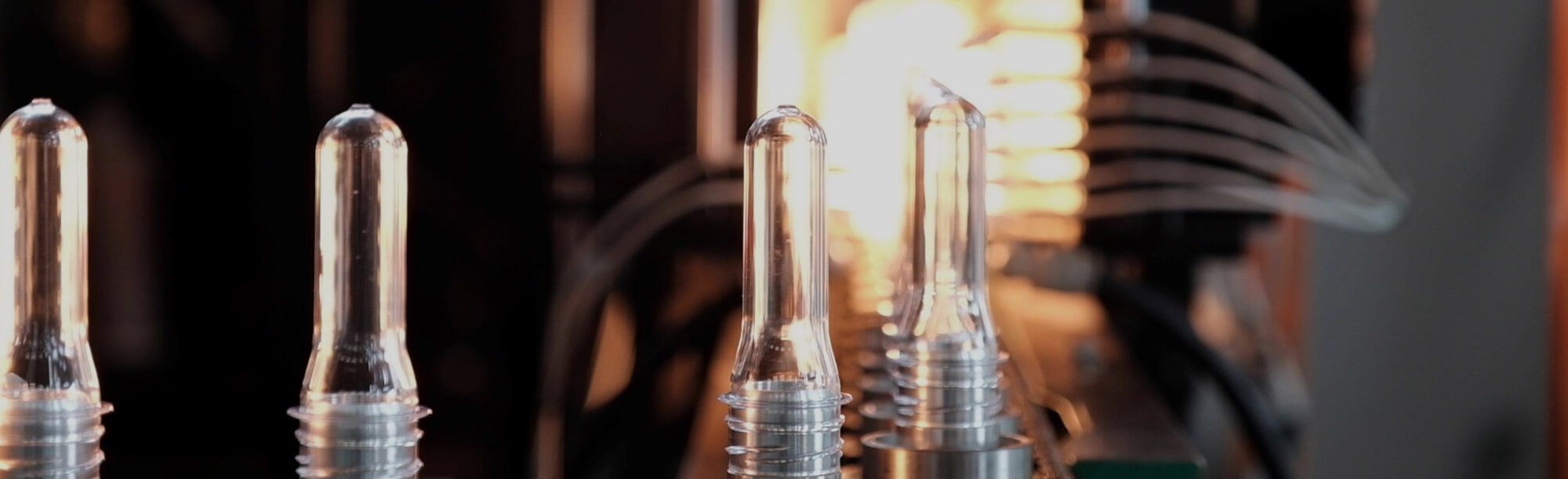

- Stable infrared heating system and independent heat balance adjusting device ensure consistency of preform heating temperature and evenness of bottle appearance color, which enhances yield.

- The heater adopts 9-section type infrared temperature adjusting control.

- Heating lamps in pre-heating zone and adjusting zone is controllable and adjustable separately.

- The real-time monitoring system will ensure technical stability.

- Two-time blowing system has real-time monitoring the pressure variation curve during the molding process of each cavity. The real-time parameter for the technical adjustment is available.

- The heating temperature and blowing time could be set according to preform and bottle shape.

- Only need to select the pre-set parameter in order to change over different preforms.

- Fully closed and transparent windows structure with safety doors to protect operator’s safety.