The ASG aseptic filling technology typically involves several steps, which may vary depending on the specific requirements of the product and the filling machine. Some common steps in the aseptic filling process include: Pre-sterilization: Before filling begins, the containers and other equipment are sterilized to remove any bacteria or other microorganisms that could contaminate the…

ABOUT ASG

High-end liquid (beverage) packaging machinery supplier in China, is able to provide integrated solution for liquid (beverage) companies around the world.

Learn More-

120

Covering an area of 120 acres

-

25+

Founded over 25 years

-

80+

Export to 80+ countries

ASG PRODUCTS

-

Learn More

Learn MoreProcess technology

CIP, water treatment, fruit juice pasteurizer, carbonated soft drinks carbonator, mineral water carbonator, etc. Everything you needed to prepare your ...

-

Learn More

Learn MoreCombiblock

With ASG CGF Blow-fill-cap combi system, multiple process in one smart solution, low cost, high efficiency, utilizing integrated equipment intelligence to ...

-

Learn More

Learn MoreStretch blow molding

ASG stretch blow molding system provides PET bottle with low energy cost no inter-mediate pollution which utilizing integrated equipment ...

-

Learn More

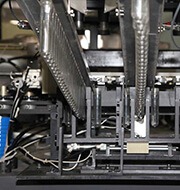

Learn MoreFilling systems

Water, juice, tea, carbonated, milk, catchup, soy sauce, household produce, and etc. ASG can always provide you all kinds of filling machine which will meet the ...

-

Learn More

Learn MoreConveyors

Modular belt conveyor, air conveyor for bottles, cans and boxes. Design in a perfect match as well as an optimum interaction between individual machines in ...

-

Learn More

Learn MoreProduct treatment

The beverage cooler and heater tunnel is able to provide maximum microbiological safety for your products, and containers. Made by stainless steel with ...

-

Learn More

Learn MoreLabeling

Hot-melt glue, cold-glue and sleeve shrink labeler, with high, stable performance as well as variety output capacity ...

-

Learn More

Learn MorePacking systems

Layer palletizer, automatic robot arm, plastic film shrink packing machine, and wrap-around case tray packer. ASG will take care of your product until the last ...

TURNKEY SOLUTION

ASG expertise in liquid packaging ensures the perfect combination of process design and product-line engineering. With the established process design system of various liquid packaging fields such as beverages, dairy products, liquors, condiments, and daily chemical products, we can provide customized turnkey solution for your project considering different packaging forms and specific factory layouts.

ASG PROJECT

As a trusted supplier, ASG has sold machines to domestic and global customers like Nestle, Coca-Cola, Pepsi, Heinz, Danone, Bright Foods, Robust, Arowana, Dongpeng Group, Tianjin Nanji, Shanghai Yanzhong, Tianjin Huaqi, etc.

ASG NEWS

Ultra-clean filling machines are a type of packaging machinery used in the beverage industry to fill containers with juice or other liquid products. These machines are designed to operate in a sterile environment and use specialized filling equipment and techniques to prevent contamination of the product. Ultra-clean filling machines are typically used for filling products…

Covid-19

During the Covid-19 pandemic, ASG is ensuring the health and safety

of our communities as well as business continuity for our customers.

Learn more