Advantages of Having a Bottle Labeler in Your Industry!

At present we can find that most of the products that are part of our daily life are labeled. But where do these labels come from?

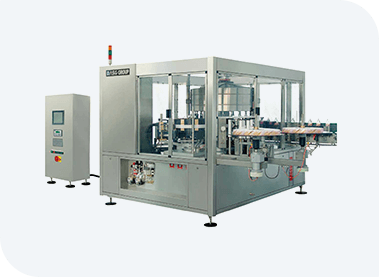

The labels come from the bottle labeling machines that, as the name says, are machines used to place labels on various objects and / or products and that are used in packaging and packaging lines which basically include the glass bottles, PET bottles as well as other packaging materials.

It is important to mention that labeling machines are also known as markers, or labeling systems and are the most common machines to solve the problems of identification, marking and labeling of all types of products.

Being very useful for various industries such as food, chemical, paper, beverages, among many more.

There is a wide variety of labeling machines; which present some similarities in the functioning and in the type of work they perform. However, they are classified according to their use or use.

Some of the labelers best known are: flat labelers, circumferences, as well as automatic labeling machines and semiautomatic; among the least known and least used are the automatic gluing labelers and hot melt labelers.

It should be noted that automatic labeling machines are among the most recommended due to their relative ease of operation, less human involvement and their ability to improve efficiency.

They are characterized by easily adapting to different product shapes and measures; for example, the bottles and other cylindrical containers, as well as different materials (plastic, cardboard, among others), thus becoming the best option to place labels on packaging and packaging.

In addition, they not only offer an efficient relationship between cost and quality, but also practicality, cleanliness and flexibility, allowing a simple and reliable label application, adapting to customer requirements.

There are lots of labeling machines for sale in the market, however, it is important to note that all of them have a package, packaging or packaging, which was designed according to the type of product to contain, therefore it is essential that it has the most information for the final consumer.

The labeling machines perform many of the sales tasks, from capturing the attention and describing the product, to making the sale. The development of a good packaging for a new product requires many decisions, the first task is to establish a packaging concept of what it should be or do for the product.

Then you have to make decisions regarding specific elements such as size, shape, material, color, text and brand sign. The packaging must go according to the advertising, the price and the distribution of the product.

The label is part of the packaging, it contains printed information about the product and these are the ones that identify the product or brand.

Labeling machines are used in the packaging of products, package packaging and packaging of large batches.

There are some similarities in the operation of the machines and in the types of work they perform. However, the diversity of products and packaging in which the labels are applied require various types of materials for labels, adhesives and methods of label application.

When making your choice of a labeling machine, it is important to contact a reputable labeling machine manufacturer. They should have experience in asset management as it helps manufacturing companies identify, evaluate, locate, redistribute and sell their surplus manufacturing equipment.