There are different types of filling machines which vary according to the different filling materials (gas-containing liquid, liquid-containing gas, rubber body, etc.) and type of containers (cans, barrels, bottles, bags, boxes, etc.). For example, we have the liquid filling machine which are used for packaging liquid materials into their designated containers. A good example of the liquid filling machine is the beverage filling machine.

There are other types of filling machines used for filling gases and more, but for the sake of this post, we are going to be considering the liquid filling machines, their use and how to choose them.What to consider when using the filling machine

What to consider when using the filling machine

Basically, the liquid filling machines are used in packaging of a wide range of liquid foods with varying viscosities. However, while using the filling machine, it is important to pay attention to factors such as;

- The type of liquid to be filled

- The temperature of packaging

- The type of container to be used in the packaging process

- The efficiency of the process: in this case, we may have to choose a suitable liquid filling machine with an appropriate level of automation

- Number of bottles or containers in the profile

- Safety of the entire filling process: here, due to special hygiene requirements in the beverage industry. Therefore, parts of the filling machine that are directly in contact with the material should be cleaned properly and no blind spots allowed. In addition, there must be reliable sealing measures to separate the wastes. The components of the direct contact materials must be made of stainless steel or non-toxic materials.

How to choose a liquid filling machine

Reasonable selection of liquid filling machines is an important way to improve economic efficiency and ensure product quality particular in the beverage industries that utilize the beverage filling machines.

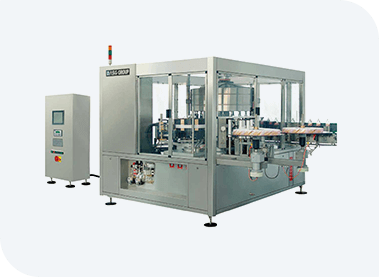

Experts said that in general, the selection of the filling machine should be closely related to the actual production, try to choose a filling machine with good quality, high efficiency, simple structure, ease of use and maintenance, small size and weight light.

So what should we choose from? According to the introduction of scientific and technological personnel, the following principles should be followed when selecting fill knowledge:

How to choose a liquid filling machine

Reasonable selection of liquid filling machines is an important way to improve economic efficiency and ensure product quality particular in the beverage industries that utilize the beverage filling machines.

Experts said that in general, the selection of the filling machine should be closely related to the actual production, try to choose a filling machine with good quality, high efficiency, simple structure, ease of use and maintenance, small size and weight light.

So what should we choose from? According to the introduction of scientific and technological personnel, the following principles should be followed when selecting fill knowledge:

First, the proper liquid filling machine should be selected according to the material properties (viscosity, foam formation, volatility, gas content, etc.) of filling to meet the needs of the production process.

For example, to avoid the loss of volatile aromatic substances, the bottle of filling or filling of atmospheric pressure should be used for liquor with a high aromatic content and in order to reduce contact with the air and ensure the quality of the products. The filled vacuum can be used for juice liquor.

Second, the production capacity of the filling machine must correspond to the production capacity of processing and packaging. There are a wide range of the liquid filling machines, as we have the linear and the rotary filling machines.